If you’ve ever tried to build a circuit board, you know there’s a lot more to it than just sticking parts on a board. Choosing the right components for your PCB is one of the most important steps you’ll take. Make the wrong choice, and you could end up with a board that doesn’t work, costs too much, or breaks down way too soon. Let’s walk through the most common mistakes people make when picking components for their boards, and how you can avoid them.

Why Your Choices Matter

Suppose you spend weeks designing your board, send it off to your printed circuit board manufacturers, and wait for your pcb prototype to arrive. When it does, you’re excited. But then you realize some parts don’t fit, or they’re not available anymore. Maybe your board overheats or it’s impossible to assemble. That’s a headache no one wants.

Getting the components of a PCB right from the start saves you time, money, and stress. It also means your custom PCB assembly will go smoothly, and your board will work just the way you planned.

Mistake 1: Picking the Wrong Size or Shape

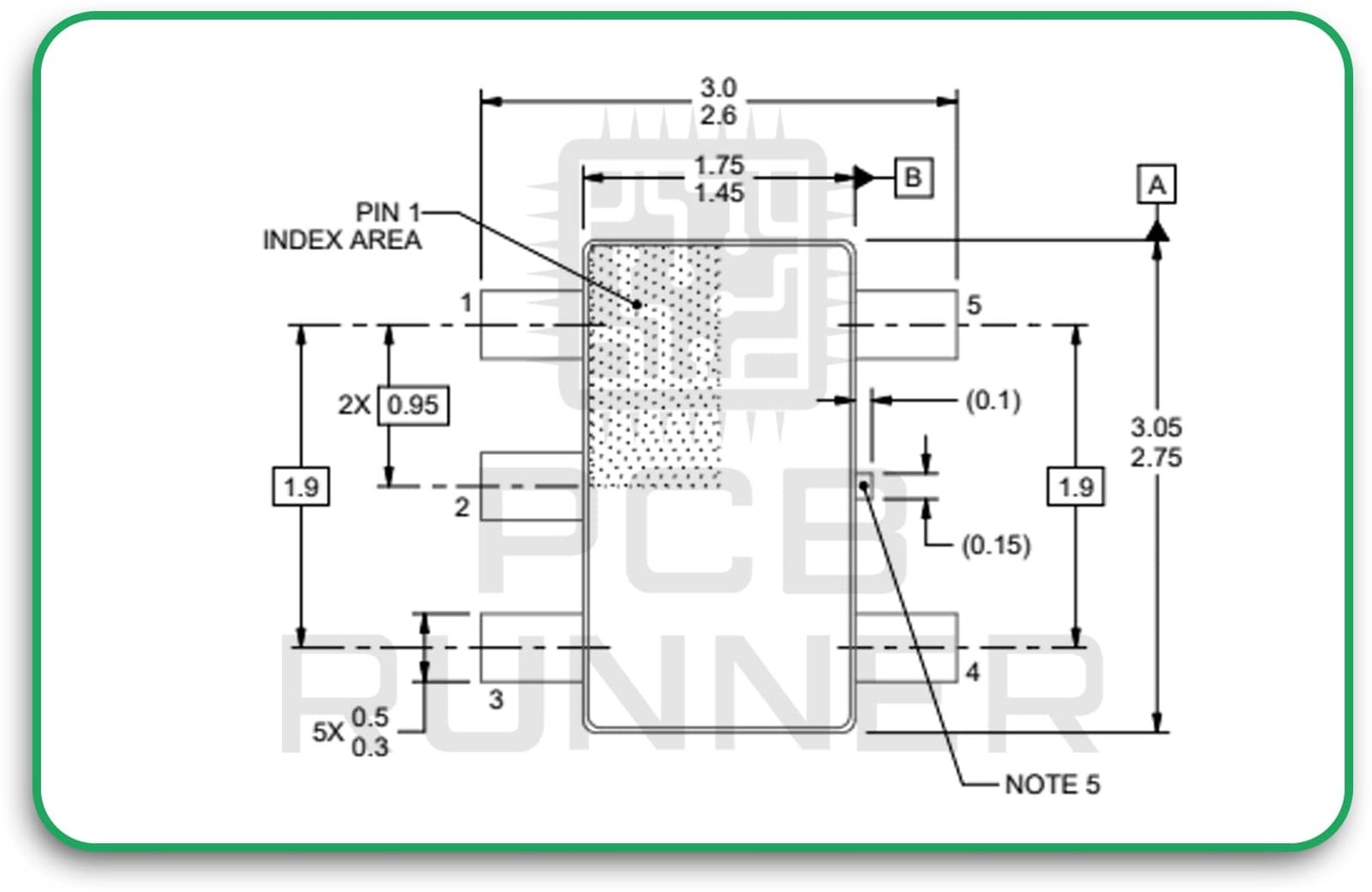

It sounds simple, but it’s a common problem. You choose a part, only to find it doesn’t fit your layout. Maybe it’s too tall, too wide, or the pins don’t match the holes. This happens a lot with smt pcb components and smt and tht components.

How to avoid it:

- Always check the datasheet for the exact size and shape.

- Use your PCB design software to double-check footprints.

- If you’re not sure, ask your PCB fabrication UK partner for advice.

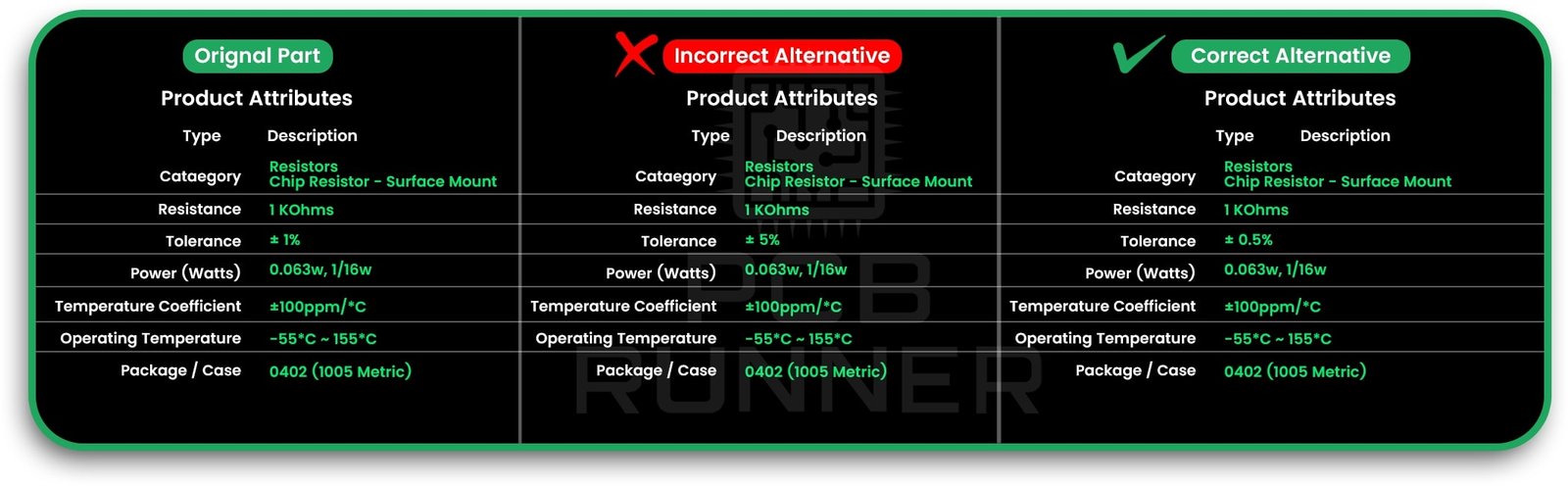

Mistake 2: Ignoring Electrical Ratings

Not all parts can handle the same amount of power. If you use a resistor, capacitor, or chip that can’t handle your board’s voltage or current, it might fail, sometimes right away, sometimes after a few weeks.

How to avoid it:

- Look for the maximum voltage and current ratings in the datasheet.

- Leave a safety margin, don’t run parts at their absolute limit.

- If your board is in a hot or cold place, check the temperature ratings, too.

Mistake 3: Forgetting About Availability

It’s easy to pick a part that looks perfect, only to find out it’s out of stock or discontinued. This can delay your project or force you to redesign your board.

How to avoid it:

- Check if your part is widely available from more than one supplier.

- Ask your printed circuit board manufacturers if they see any supply issues.

- Keep a list of backup parts, just in case.

Mistake 4: Not Thinking About Assembly

Some components are easy to place by machine. Others need to be soldered by hand. Mixing too many types, like SMT electronic components and through-hole parts, can make your custom PCB assembly more complicated and expensive.

How to avoid it:

- Stick to SMT PCB components when you can, especially for small boards.

- Use through-hole parts only for connectors or significant, heavy parts.

- Make sure there’s enough space between parts for soldering and inspection.

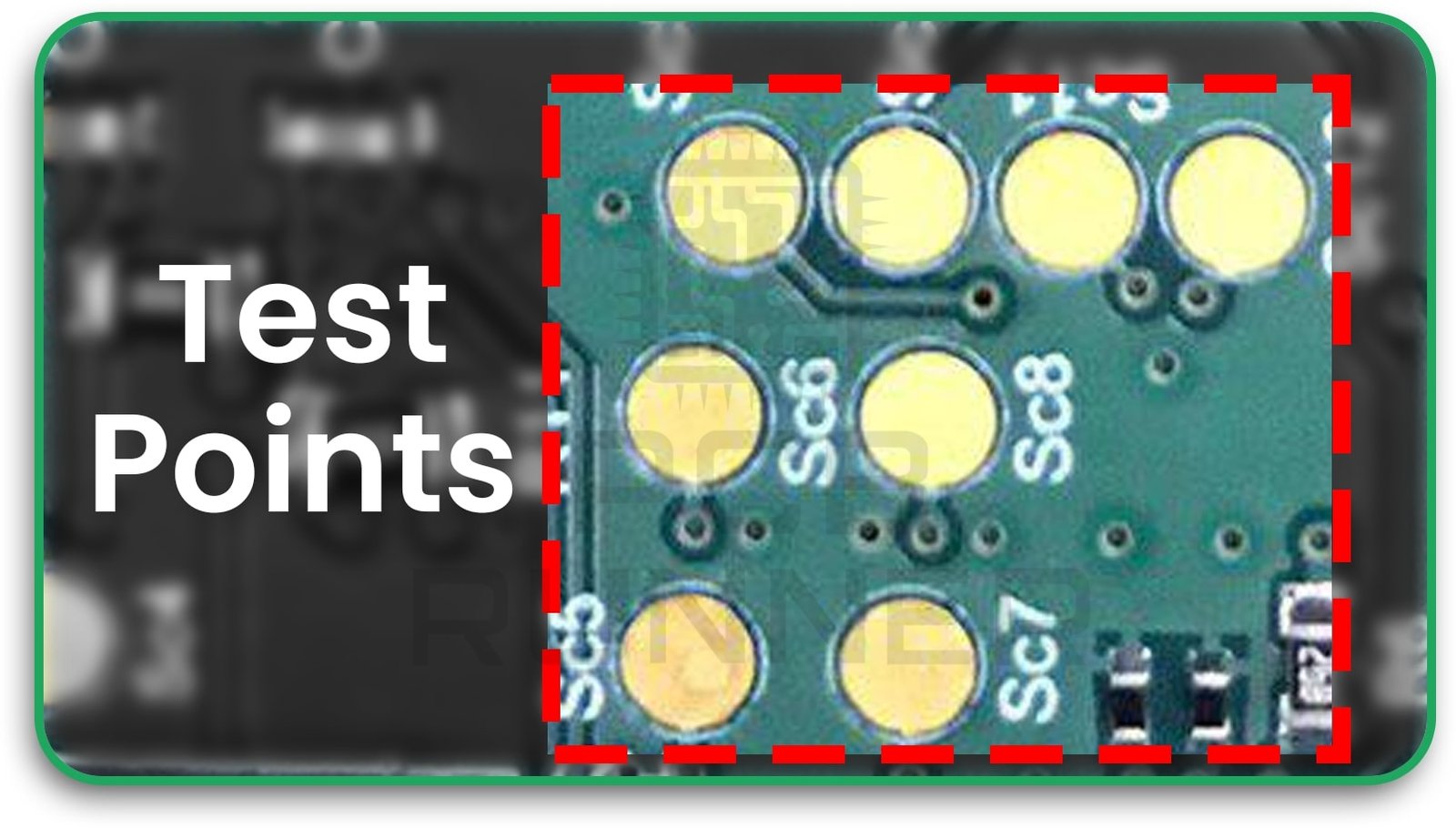

Mistake 5: Overlooking Testing Needs

If you don’t plan for testing, you might have trouble finding and fixing problems later. This is especially true for boards with lots of smt and tht components.

How to avoid it:

- Add test points for necessary signals and power lines.

- Make sure test points are easy to reach.

- Use clear markings for polarity and orientation so parts aren’t placed backwards.

Mistake 6: Using Cheap or Unknown Suppliers

Cheap parts can be tempting, but they often cause more trouble than they’re worth. You might get parts that don’t work, don’t last, or don’t match the datasheet.

How to avoid it:

- Buy from trusted suppliers and printed circuit board manufacturers.

- Ask for certificates of quality, especially for essential parts.

- Test a small batch before you order a lot.

Mistake 7: Not Documenting Your Choices

If you don’t keep good records, it’s easy to forget which parts you picked, or why. This can slow down your project or lead to mistakes during assembly.

How to avoid it:

- Make a bill of materials (BOM) with part numbers and suppliers.

- Update your BOM every time you change a part.

- Share your BOM with your PCB fabrication UK team and assembly partners.

Best Practices for Choosing PCB Components

- Start with a clear list of what you need your board to do.

- Pick parts that are easy to find and have a long life ahead.

- Double-check sizes, shapes, and electrical ratings.

- Stick to smt electronic components for most of your design unless you have a good reason not to.

- Make sure your board is easy to assemble and test.

- Keep your documentation up to date.

Final Thoughts

Choosing the right components of a PCB isn’t just about picking what’s cheapest or most popular. It’s about making sure your board works, lasts and can be built without trouble. Take your time, check your work, and don’t be afraid to ask your PCB fabrication UK or printed circuit board manufacturers for advice. Good choices now mean fewer problems later, and a board you can be proud of.

FAQs: PCB Component Selection

1. Why is it essential to use smt pcb components?

SMT parts are small, easy to place by machine, and help you make compact boards. They also speed up custom PCB assembly and lower costs.

2. What’s the difference between SMT and tht components?

SMT components sit on top of the board and are soldered by the machine. THT (through-hole) parts have leads that go through the board and are often soldered by hand.

3. How do I know if a component will fit my board?

Check the datasheet for measurements, and use your PCB design software to match the footprint.

4. What should I do if a part is out of stock?

Always have backup options in your BOM. Ask your printed circuit board manufacturers for help finding replacements.

5. Can I mix smt and tht components?

Yes, but it can make assembly slower and more expensive. Use smt pcb components for most of your board, and save tht for special parts.

6. How do I make sure my board is easy to test?

Add test points for necessary signals and keep them easy to reach. Use clear markings for part orientation.

7. Should I buy the cheapest parts?

Not always. Cheap parts can fail or cause problems. Buy from trusted suppliers and test new parts before using them in big orders.

8. What’s the role of the PCB prototype in component selection?

A PCB prototype lets you test your design and catch mistakes before full production. It’s a smart step that can save you time and money.