The defence sector in the UK and Europe is moving at a rapid pace. As threats change and technology advances, so does the need for smarter, more reliable systems. At the heart of this progress is the humble printed circuit board (PCB). Today, PCBs are not just the backbone of electronics, they are the driving force behind innovation, helping defence businesses scale and succeed.

Why PCBs Matter in Defence

Every modern defence device, from radar systems to unmanned drones, relies on PCBs. Without them, there would be no signal processing, power management, or secure communications. The demands in defence are challenging: PCBs must survive heat, moisture, shock, and even radiation. They must also meet strict standards for quality and security because failure is not an option in the field.

PCB Production UK: Supporting Local Defence Growth

For defence companies in the UK, working with local PCB production partners offers significant advantages. Quick turnaround, easier communication, and compliance with UK and EU defence standards are just the start. PCB production UK facilities are set up to handle everything from rapid prototyping to full-scale manufacturing, giving your business the flexibility to move fast and scale up when needed.

Meeting Defence Standards: Why It’s Critical

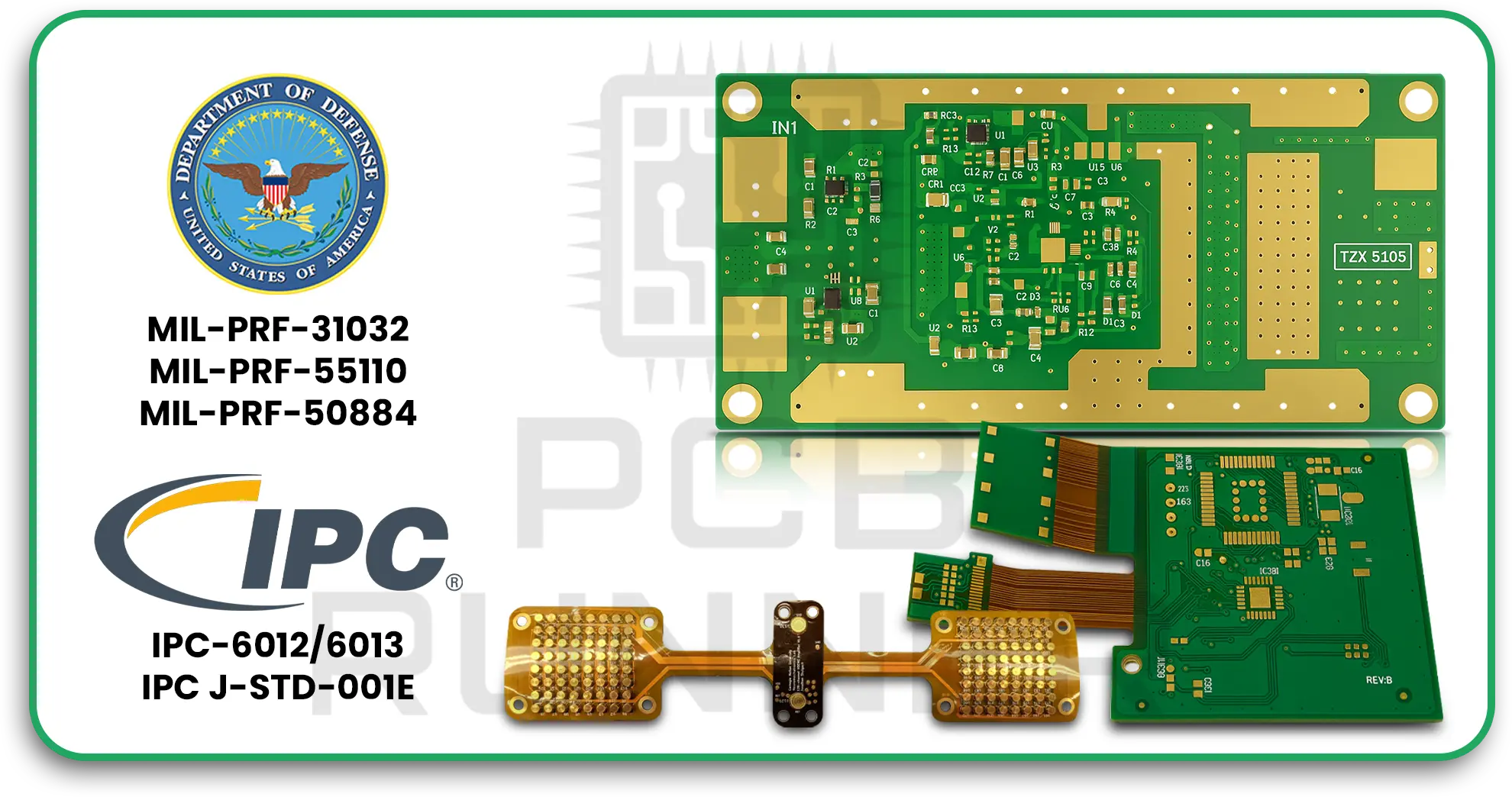

Defence PCBs are held to some of the highest standards in the world. They must meet military specifications like MIL-PRF-31032 for design and manufacturing and IPC-6012/6013 for performance and reliability. These standards ensure that your boards will work in the toughest environments, whether in a submarine, a jet fighter, or a satellite.

Key Defence Standards for PCB Manufacture

MIL-PRF-31032: General military PCB requirements

MIL-PRF-55110: Rigid PCB requirements

MIL-PRF-50884: Flexible PCB requirements

IPC-6012/6013: Rigid and flexible PCB performance

IPC J-STD-001E: High-reliability electronic assembly

Working with printed circuit board manufacturers who understand and follow these standards is essential for your business’s reputation and success.

How PCB Manufacture Drives Defence Innovation

PCBs are not just components, they are enablers of new ideas. Here’s how PCB manufacturing is helping defence businesses grow:

- Miniaturisation: Modern PCBs allow more features in smaller packages. This means lighter drones, smarter wearables, and compact guidance systems.

- Reliability: Advanced manufacturing ensures that boards survive extreme conditions, from arctic cold to desert heat.

- Security: PCBs can be designed with hardware encryption and secure domains, protecting sensitive data and communications.

- Speed: Rapid prototyping and production mean defence projects can move from idea to field deployment in record time.

IoT PCB: The Next Frontier

The Internet of Things (IoT) is transforming defence. IoT PCBs connect sensors, vehicles, and bases, allowing real-time data sharing and smarter decision-making. From tracking assets to monitoring soldiers’ health, IoT PCB design is opening new possibilities for defence operations.

Key Features of IoT PCBs in Defence

- Low Power Consumption: Essential for battery-powered sensors in the field.

- Rugged Construction: Withstands shock, vibration, and moisture.

- High Security: Hardware-based encryption to protect mission-critical data.

- Miniaturisation: Fits advanced features into small, lightweight devices.

Applications: Where PCB Innovation is Making an Impact

Let’s look at real-world defence applications where PCB innovation is a true catalyst for business growth:

1. Communication Systems

Modern military communications rely on robust PCBs that can handle high frequencies and resist electromagnetic interference. Secure, reliable PCBs ensure that information flows smoothly, even in harsh conditions.

2. Radar and Sonar

Radar and sonar systems need PCBs that can process high-frequency signals and manage heat. Advances in PCB manufacture allow for better signal integrity and thermal management, making systems more effective and reliable.

3. Guidance and Navigation

Drones, missiles, and vehicles depend on PCBs that integrate sensors, control systems, and navigation features. Miniaturised, rugged PCBs enable precise control and long-lasting performance.

4. Electronic Warfare

PCBs for electronic warfare must manage complex signal processing and withstand high power. They also need to be flexible and secure, adapting to new threats quickly.

5. Unmanned Systems

From aerial drones to underwater vehicles, systems need lightweight, power-efficient PCBs. IoT PCB manufacturers are leading the way in integrating multiple subsystems on a single board.

6. Soldier Systems

Wearable tech for soldiers, like smart helmets and health monitors, uses flexible, durable PCBs. These systems help keep troops safe and informed, even in harsh environments.

Scaling Your Defence Business with PCB Innovation

If you want to grow your defence business, focusing on PCB-driven innovation is key. Here’s how you can get started:

1. Work with Experienced PCB Manufacturers

Choose printed circuit board manufacturers with a track record in defence. They’ll understand the strict requirements and help you avoid costly mistakes.

2. Invest in Rapid Prototyping

Use local PCB production UK services to develop prototypes quickly. This lets you test new ideas, fix problems early, and get to market faster.

3. Embrace IoT PCB Design

IoT is the future of defence. Partner with IoT PCB manufacturers who can design and build boards for smart sensors, connected vehicles, and secure communications.

4. Prioritise Reliability and Security

Make sure your PCBs meet or exceed defence standards. Ask about testing, certification, and security features like hardware encryption.

5. Plan for Scale

As your business grows, you’ll need to move from small batches to full-scale production. Work with partners who can scale up quickly without sacrificing quality.

Emerging Trends: What’s Next for Defence PCBs?

The defence sector is constantly evolving. Here are some trends to watch:

- Flexible and Stretchable PCBs: For wearable tech and conformal sensors.

- AI Integration: PCBs with built-in processors for artificial intelligence and edge computing.

- Radiation-Hardened Boards: For space and nuclear applications.

- Cybersecurity by Design: Boards with built-in security features to resist cyber threats.

Overcoming Challenges in Defence PCB Manufacture

Designing and building PCBs for defence isn’t easy. You’ll face challenges like:

- Wide Bandwidth Needs: Electronic warfare and communications need boards that handle many frequencies.

- Thermal Management: High-power systems generate heat, so boards must dissipate it efficiently.

- Miniaturisation: Fitting more features into smaller spaces without losing reliability.

- Environmental Durability: Boards must survive in extreme cold, heat, moisture, and vibration.

- Security: Protecting sensitive technology from hacking and reverse engineering.

The solution? Work with experts who know defence standards and have experience in advanced PCB manufacture.

Actionable Steps for Defence Businesses

If you’re ready to scale your business with PCB-driven innovation, here’s what to do:

- Audit your current suppliers: Are they meeting defence standards? Can they scale with you?

- Explore new materials and designs: Ask about flexible, high-density, or radiation-hardened PCBs.

- Invest in IoT PCB design: Start small with asset tracking or soldier health monitoring, then expand.

- Focus on compliance: Keep up with changing defence standards and certifications.

- Build partnerships: Collaborate with local PCB production UK partners for faster turnaround and better support.

Final Thoughts

PCB innovation is more than a technical upgrade, it’s a business catalyst for the defence sector. By embracing advanced PCB manufacture, investing in IoT PCB design, and working with experienced printed circuit board manufacturers, your business can lead the way in the UK and Europe. Whether you’re building smarter drones, secure communications, or wearable tech for soldiers, the right PCB partner will help you scale and succeed.