Achieving quality, accountable, and efficient manufacturing output is imperative for seamless electronics production, especially for manufacturing turnkey EMS providers. These Electronic Manufacturing Services (EMS) providers are responsible for the entire value chain, including PCB fabrication and assembly, testing, packaging, and logistics. By integrating everything in one compartment, these firms are able to help businesses lower costs, improve timelines for production, and uphold impeccable quality.

If you are a start-up launching a novel device or a seasoned firm scaling up production, working with a turnkey EMS provider will improve the overall manufacturing experience. In this article, they will explain the factors concerning how turnkey EMS providers enhance product quality, what services they offer, and how to choose the correct partner for your business.

What is a Turnkey EMS Provider?

Turnkey EMS providers develop a company’s product design into a finished product utilizing in-house capabilities or through contracted suppliers. For example, they could implement procurement services, Assembly, and Test services, among others. Firms no longer have to cope with a myriad of vendors regarding PCB fabrication, components sourcing, assembly, and quality assurance.

There is increased efficiency due to time savings, lack of risk, and improvement in product quality. With the integration of engineering skills, efficient manufacturing, and depth in supply chain management, turnkey solution providers bestow businesses with effortless production.

EMS Turnkey Providers’ Tasks

1. PCB Fabrication

A Turnkey EMS service provider customizes its services and works with reputable PCB manufacturers to meet its customers’ specific fabrication services, such as:

- Multi-layered PCB fabricating

- Flex and rigid-flex PCB fabricating

- HDI PCB fabrication

- PCB material selection

- PCB layer stack-up optimization

2. Component Sourcing and Supply Chain Management

Electronics manufacturing faces numerous challenges, among which, sourcing high-grade components at favorable prices is challenge number one. The ever-increasing competition in the market makes it difficult to obtain genuine, good-quality parts at decent prices. An EMS provider can resolve these struggles with the help of its:

- Network of global suppliers

- Ability to negotiate better rates

- Stability of the supply chain

3. PCB Assembly (PCBA)

PCBA is one of the final steps before the introduction of the product into the market. Unlike other companies, EMS providers demonstrate significant proficiency in the precise assembly of PCBs and offer various services such as:

- Surface Mount Technology assembly (SMT)

- Through Hole Technology (THT) assembly

- Hybrid Assembly

- Durable automated soldering techniques

4. Testing and Quality Assurance

Turnkey EMS service providers have implemented numerous measures to ensure reliability, one of them being advanced testing procedures. These include:

- Functional Testing (FCT)

- X-ray inspection of concealed solder joints

- Automated Optical Inspection

- In-Circuit Testing (ICT)

5. Box Build Assembly and Final Integration

EMS providers, in addition to support with PCB assembly, also provide full box build capabilities, where they design and implement:

- Integration of the product

- Casing and enclosure construction

- Assembly of wires and cables

- System configuration and software loading

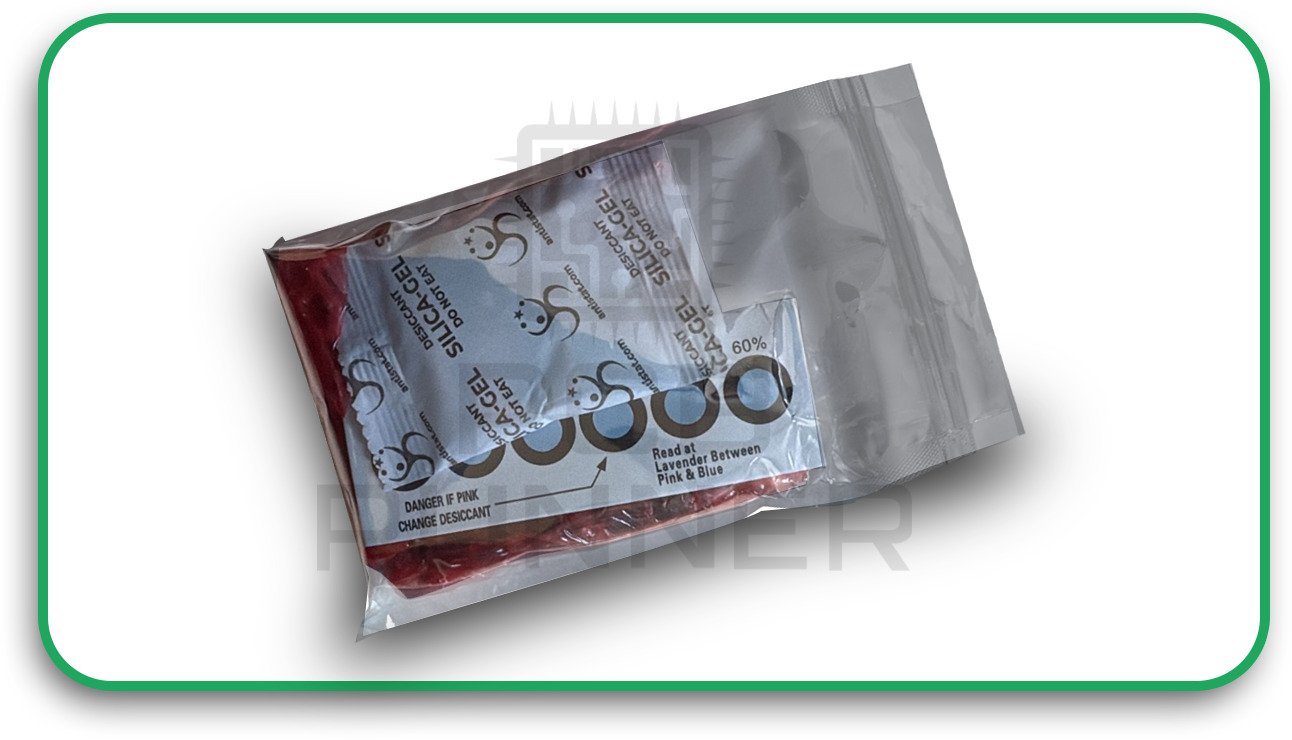

6. Logistics, packaging, and after-sales support.

Most EMS providers offer assistance with the following:

- Packaging tailored to your needs

- Products are shipped individually to the customer.

- Together with warranty services, we also provide product maintenance.

The Impact of Turnkey EMS Providers on Quality Improvement

1. Achieving Quality through Conformance

All processes of a turnkey EMS provider are executed through verifiable standard operating procedures which guarantee the same level of quality for every single lot produced.

2. Lowered Error and Defect Rates

Using automated assembly with computer-aided inspection and precision testing eliminates the possibility of human error while decreasing the rate of defects.

3. Shorter Time Required to Introduce the Product to the Market

Improved workflow in production allows for faster rollout of products, enabling companies to outperform competitors.

4. Lower Operating Costs

With numerous vendors, cost escalation is inevitable. A turnkey EMS provider reduces costs without lowering the service level by streamlining supply chains.

5. Meeting Industry Requirements

Most reputable EMS providers ensure that their products meet internationally accepted quality requirements, such as:

- ISO 9001:2015 (Quality Management Systems)

- IPC-A-610 (Electronic Assemblies Acceptability)

- RoHS (Restriction of Hazardous Substances)

- ISO 13485 (Medical Device Manufacturing)

Good Practices for Selecting a Turnkey EMS Partner

While choosing an EMS partner, specifically, monitor their:

1. Capability Claims

Confirm they have experience in supplying your application’s PCB fabrication, assembly, and testing.

2. System for Quality Assurance

Do they provide in-house product testing, certifications, and reliability tests for consistent outcomes?

3. Supply Chain Robustness

A reliable supplier network guarantees the availability of authentic parts and reduces the possibility of delays or scarcity.

4. Flexibility in Production

Your EMS contractor ought to manage both low to mid-range and high production volumes without sacrificing the quality or speed of delivery.

5. Communication and Customer Service

It is essential to select a partner that guarantees reliable communication and prompt response to customer and technical support requests.

Recent Developments in Turnkey EMS Manufacturing

1. Smart Manufacturing and Industry 4.0

Most EMS contractors have incorporated the use of AI-powered robotics automation, IoT integration, and industrial data analytics to enhance the efficiency of their production processes.

2. High-Density Interconnect (HDI) PCBs

As the world becomes more technology-inclined, EMS contractors are increasingly becoming proficient in the fabrication of miniaturized electronics, and therefore, specializing in HDI PCB fabrication becomes mandatory.

3. Environmentally Sustainable and Lead-Free Manufacturing

With the adoption of RoHS guidelines, many EMS contractors are beginning to utilize lead-free soldering and eco-friendly materials.

4. Rigid-Flex and Flexible PCBs

EMS contractors can now fabricate flexible PCBs intended for use in wearable devices, medical implants, and aerospace applications.

5. Quality Control Using Artificial Intelligence

Quality control is improved by automated error detection employing AI, thus increasing yield rates and product reliability.

Final Thoughts

Working with a turnkey EMS provider ensures better product quality, lower production costs, and faster delivery times. These providers simplify the manufacturing process by assuming full responsibility for PCB fabrication through to final assembly and guarantee the delivery of high-reliability electronics. Partnering with a reliable EMS provider can help you maintain quality standards while bringing your PCB-manufactured products to market faster than anticipated.

Are You in the Search for Dependable EMS Services?

PCB Runners is here to monetize your ideas and projects by providing you with effortless turnkey PCB design and assembly services. Reach out for a free estimation today!

FAQs

1.What comes to mind when discussing a turnkey EMS provider?

A turnkey EMS provider assumes full responsibility for the production of electronics including board design, board assembly, and product assembly and shipping.

2. What are some advantages of using a turnkey EMS provider?

A cut in costs, fewer mistakes, an increase in production speed, and an overall better product are all advantages gained by using an EMS provider.

3. How does the product quality assurance system work with an EMS provider?

High reliability of products is achieved through numerous stages of testing, automated assembly processes, and following certain industry standards by an EMS provider.

4. What sectors does remote EMS service provide help?

Consumer electronics, medical, aerospace, automotive, and industrial automation are some industries that purchase equipment through EMS providers.

5. What steps do I take to find suitable and reliable EMS for my project?

When looking to partner with an EMS, their technical capabilities, levels of quality control, supply chain, ability to scale, and customer service responsiveness should be considered.